Supercritical CO2 uses have grown substantially over the past three decades. The evolution of equipment and processes from early applications of decaffeination of coffee to compound extraction from biomass to analytical chemistry to polymer production to medical sterilization has grown consistently and is now accelerating in a significant way.

As scCO2 becomes more widely recognized, and the low temperature, non-reactive, penetrating attributes of the material are better appreciated, applied research projects are growing exponentially.

Explore how your team can take advantage of scCO2 sterilization in your development process.

Explore scCO2 Technology

Explore scCO2 Equipment

Explore scCO2 Services

Material Compatibility Testing

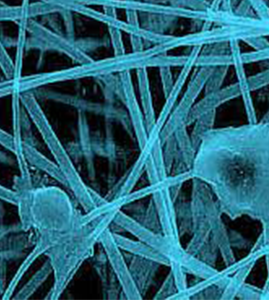

The low temperature and inert nature of supercritical carbon dioxide (scCO2) make it ideal for processing a wide variety of products, materials, and devices. NovaSterilis has evaluated hundreds of products as either standalone materials or devices, which often are comprised of combinations of interconnected materials. The products range from basic surgical tools, tissue products, pharmaceuticals, 3D printed materials, bioresorbable devices, to multi-use complex devices such as endoscopes.

NovaSterilis is committed to assessing, testing, and solving your material compatibility challenges. Contact our applications leader to discuss your specific opportunity.

Visit our Tools and resources Page to download our Material, Device, or Therapeutics Compatibility Guide(s).