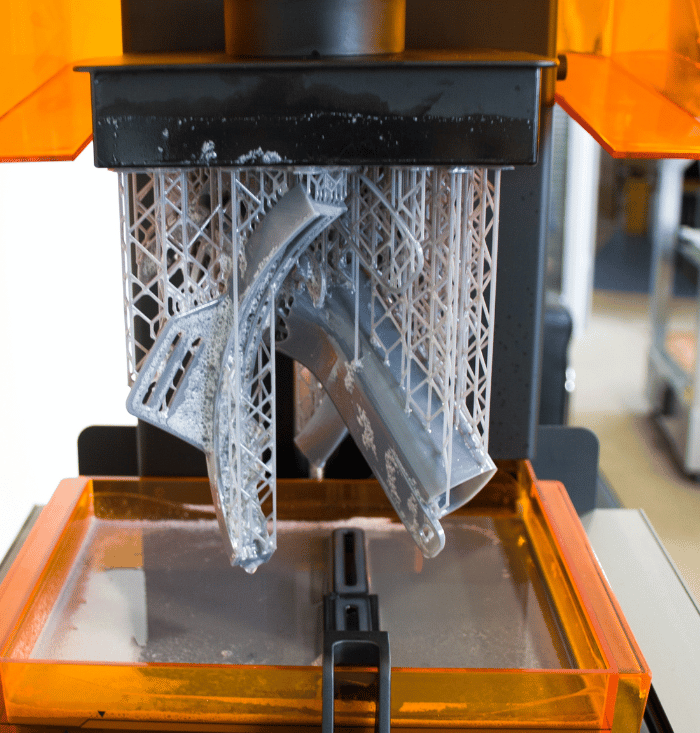

Advancements in 3D printing, combined with novel biomaterials that can be used within the additive manufacturing process, has generated a growing number of medical devices requiring terminal sterilization. Biomaterials, polymers, and metals can all be present in novel regenerative medicine products, making these devices acutely sensitive to traditional sterilization methods which rely on harsh conditions to achieve sterility.

The ability to print three dimensional structures that serve as matrices for regenerative medicine has opened up a need for low temperature and gentle sterilization processes. NovaSterilis has the technology expertise for terminal sterilization of such complex and sensitive devices.

The innovation in additive manufacturing means that biomaterial suppliers will need to sterilize their specialty materials, and device manufacturers will need to sterilize their final products.

NovaSterilis’ proof-of-concept testing program enable medical device teams to assess the compatibility of their components and final products with scCO2 sterilization.

NovaSterilis scCO2 Advantages:

- Compatible with a wide range of materials and states of matter, making it suitable for many formulations that include a diverse array of ingredients.

- Sterilizes dry products, products that are hydrated, and products that exist as a liquid.

- Low temperature (~35°C), gentle terminal sterilization process minimizes the impact to native materials.

- Broadly compatible with sensitive natural and synthetic polymers.

- scCO2 can be used to clean microstructures of polymers.

Additive Manufacturing Offerings:

NovaSterilis understands that finding a sterilization method that is compatible and does not degrade or negatively impact the functionality of the material being sterilized is essential in the additive manufacturing industry.

- Challenge: Traditional sterilization methods like gamma radiation and autoclaving can damage the delicate proteins within bioinks, compromising their viability and printability. In addition, high temperatures negatively impact the functionality and performance of bioinks.

- Solution: Supercritical CO2 (scCO2) sterilization offers a gentle and effective alternative. scCO2 penetrates deeply into the bioink without harming sensitive components, preserving viability and maintaining printing fidelity. This enables the creation of high-resolution, biologically active tissues and organs for 3D bioprinting applications in regenerative medicine, drug discovery, and tissue engineering.

- Challenge: Individual bioink components, like natural polymers and proteins, might have varying sterilization requirements, making it challenging to find a method suitable for all components without compromising their functionality.

- Solution: scCO2‘s tunable properties allow for precise control of pressure and temperature, enabling targeted sterilization of different bioink components while preserving their bioactivity. This versatility overcomes the limitations of traditional methods. This opens up the possibility of using a wider range of biocompatible materials in bioink design, leading to the development of more complex and functional bioprinted tissues.

- Challenge: Many polymers used in 3D printing are susceptible to heat and chemical degradation during traditional sterilization, altering their mechanical properties and potentially leaching harmful byproducts.

- Solution: scCO2‘s low critical temperature and chemical inertness make it ideal for sterilizing 3D printed polymers without compromising their structural integrity or introducing toxic residues. As opposed to sterilization, scCO2 can also be used to clean polymers after printing. This ensures the safety and efficacy of 3D printed medical devices, implants, and prosthetics, promoting their use in various healthcare applications.

- Challenge: Traditional sterilization methods can oxidize or corrode metallic inks, affecting their conductivity and printability. Additionally, some metals might not be compatible with high temperatures or harsh chemicals used in conventional sterilization.

- Solution: scCO2‘s gentle nature and tunable properties allow for sterilization of metallic inks without causing surface damage or altering their electrical properties. This compatibility expands the range of metals usable in 3D printed electronics and biomedical devices. This paves the way for the development of next-generation biocompatible and functional metallic inks for applications in implantable electronics, biosensors, and microfluidic devices.

Why NovaSterilis: