EO Sterilization Challenges

- EO is under regulatory pressure from FDA and EPA

- Recent litigation has increased risk profile of EO sterilization

- Slow turnaround times

- Expensive emissions scrubbing costs

- EO processing costs are increasing dramatically due to regulation:

- Emission standards require costly facility upgrades

- Closure of contractor EO processing facilities

Solutions

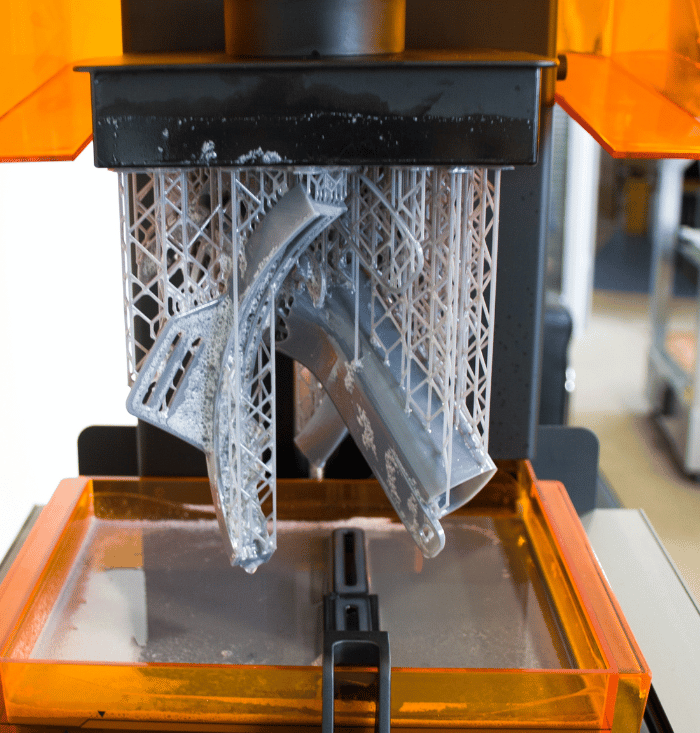

- Shorter turnaround times – (measured in hours not days)

- Environmentally friendly solution – recipient of EPA Green Chemistry Award

- FDA Challenge Grant I recipient

- Cost effective – operating costs less expensive than ethylene oxide (EO) sterilization

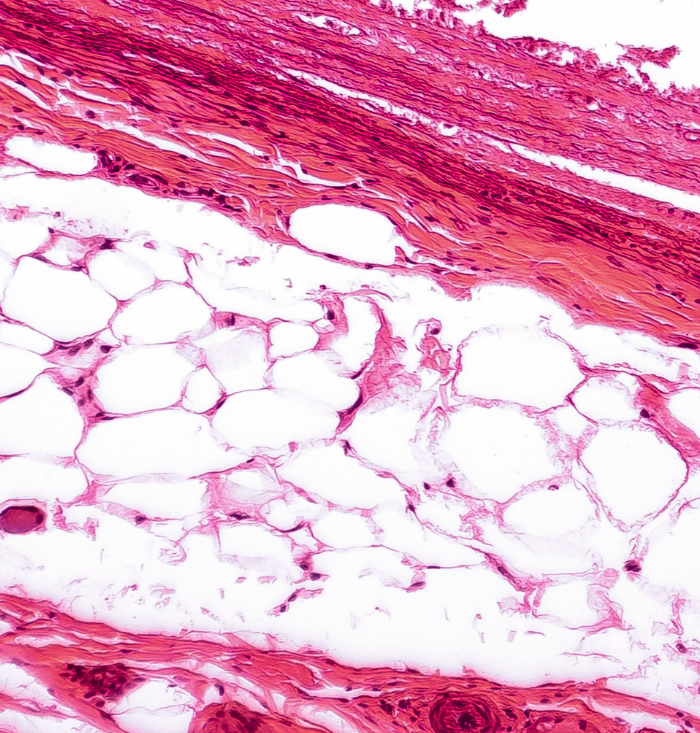

- Broadly compatible with biomaterials

Success Stories

FDA Story

- Agency looking to broaden commercial use of EO alternative sterilization modalities

- Selected as one of 4 Innovation Challenge Grant recipients

- Bimonthly meetings with the FDA to streamline the adoption rate of scCO2

NovaSterilis Provides

- Multiple regulatory clearances received