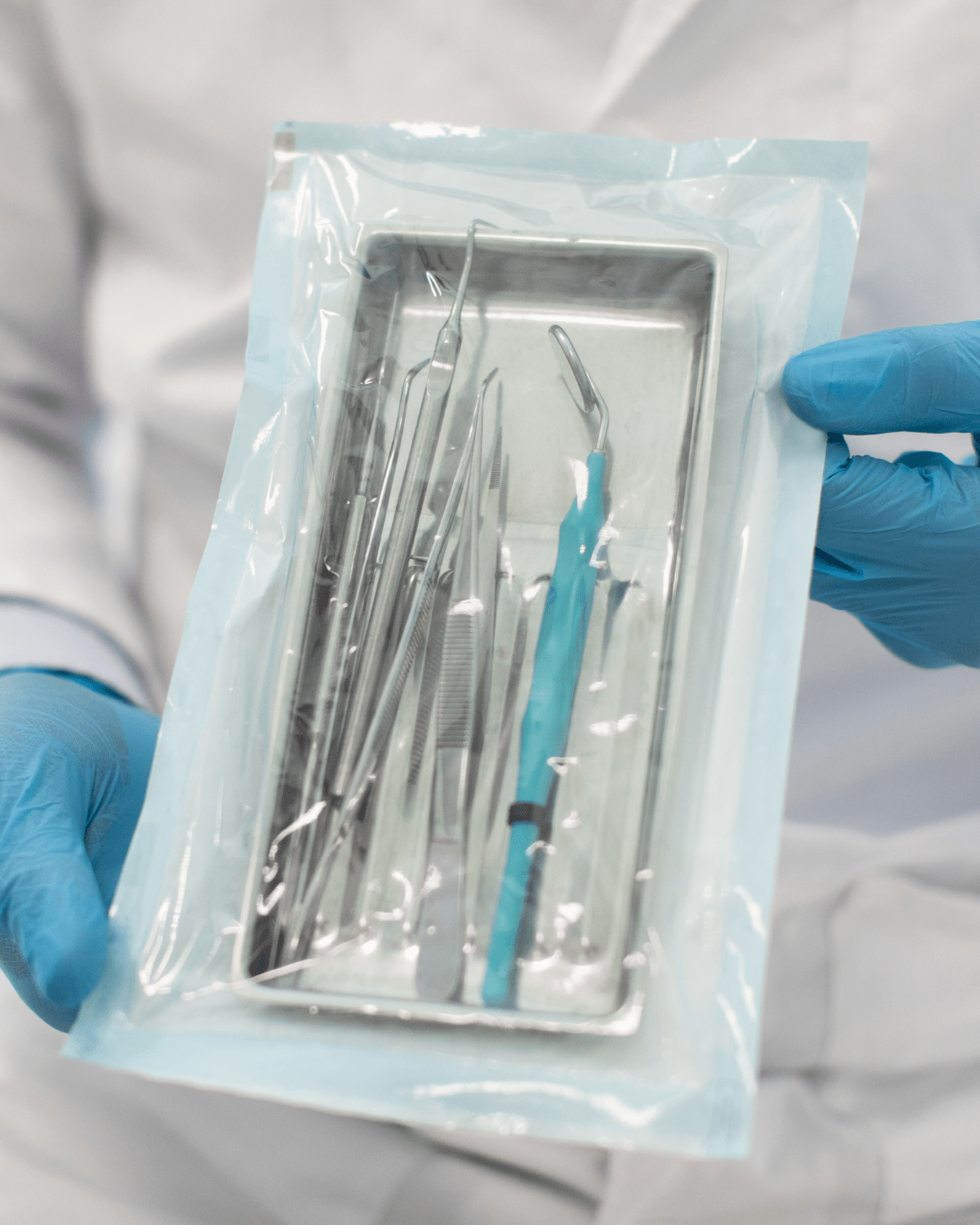

NovaSterilis recognizes the importance of delivering safe, sterile medical devices to end users around the globe. With the growing complexities of medical devices, choosing the right sterilization method is essential to ensure the highest quality standards are met.

Traditional sterilization methods often do not have the penetrating capability to sterilize hard-to-reach places in complex medical devices and are often incompatible with the variety of natural and synthetic materials being incorporated into emerging medical devices. scCO2 offers a more effective, safer terminal sterilization solution.

Although traditional sterilization methods have historically been able to penetrate to achieve sterility, today’s device complexities have limited the effectiveness of traditional modalities, specifically when dealing with natural and synthetic polymers and bioactives. Supercritical CO2 offers an effective and clear terminal sterilization solution.

Historically, EtO and Gamma were used because devices would withstand the harsh conditions used to achieve sterility. Today, as devices become more sensitive, alternative sterilization modalities are required to preserve the functionality of the devices being sterilized. Supercritical CO2 is one of the solutions that is effective for the materials that are temperature and chemically sensitive.

NovaSterilis has experience providing supercritical CO2 contract sterilization services and in-house processing equipment to the medical device industry. The NovaSterilis team follows specific processes when determining compatibility with scCO2 sterilization, considering a number of factors including the functionality, design, material composition, and packaging of the medical device.

NovaSterilis Advantages:

scCO2 sterilization is capable of penetrating torturous paths and rendering devices with long lumens sterile in a matter of a few hours.

scCO2 sterilization is compatible with a broad variety of natural and synthetic components making it an ideal sterilization method for medical devices that are comprised of many different materials.

scCO2 is low-temperature, non-toxic, and minimally reactive.

scCO2 sterilization is a terminal sterilization solution that can replace aseptic manufacturing, which can be costly and requires a significant amount of time and expertise to perform the requisite quality monitoring.

NovaSterilis’ sterilization process achieves a medical device industry standard of SAL6 with minimal to no impact.

NovaSterilis has a long-standing relationship with the FDA through its selection as a participant in the FDA Innovation Challenge Grant 1.

Industries Served

- Wound Care

- Complex Medical Devices

- Orthopedics

- Maxillofacial Plastic and Reconstructive Surgery

Device Types:

- Hydrogels

- Hemostats

- Extracellular Matrix (EMC)

- Collagen ingredients

- Multi-channel Endoscopes

- Long Lumen Devices

- Batteries

- Glucose monitoring systems (GMS)

- Demineralized Bone Matrix (DBM)

- Femoral Heads

- Metallic/Polymer plates and screws

- Ceramic bone fillers

- Synthetic scaffolds

- Hyaluronic based Dermal fillers

- Adipose fillers

Why NovaSterilis: